Contact Us

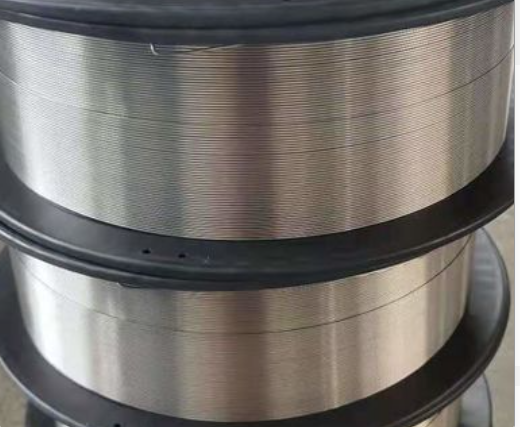

When it comes to durable and versatile materials, pure titanium wire stands out as a top contender. Renowned for its exceptional strength-to-weight ratio and corrosion resistance, this remarkable metal has found a wide range of applications in various industries. In this blog, we will delve into the incredible features and uses of pure titanium wire, truly a testament to its remarkable purity.

Pure titanium wire is known for its unparalleled strength and lightness. Its specific strength and weight make it an ideal choice for applications that require materials to withstand high stress and strain, while also being lightweight. Additionally, pure titanium wire boasts incredible corrosion resistance, making it suitable for use in harsh environments. These impressive properties set it apart from other materials, establishing titanium wire as a reliable and superior option.

Pure titanium wire finds extensive use in a myriad of industries. In the medical field, it is commonly used for dental implants and orthodontic wires due to its biocompatibility. Its resistance to corrosion and the ability to bond with bone make it an excellent choice for these applications. Pure titanium wire also plays a crucial role in aerospace and marine industries, where its lightweight nature and resistance to saltwater corrosion make it highly sought after. Moreover, it finds utility in the automotive industry, particularly in exhaust systems, as it can withstand high temperatures and corrosive gases. These diverse applications highlight the versatility and indispensability of pure titanium wire.

The production of pure titanium wire involves several important manufacturing processes. Initially, the titanium ore is extracted from mineral deposits and processed through various purification techniques to obtain pure titanium. Once purified, the titanium is then transformed into either titanium sponge or titanium powder. These materials serve as the basis for the production of titanium wire. The titanium sponge or powder is melted and then wrought, meaning it is subject to hot and cold working until it reaches the desired shape and dimensions. This process ensures that the resulting pure titanium wire possesses the required strength and ductility for its intended applications.

With advancements in technology, the production and application of pure titanium wire continue to evolve. Researchers and engineers are constantly striving to enhance its properties and develop new alloys and compositions. One notable development is the introduction of titanium alloys, wherein other elements like aluminum or vanadium are added to improve specific characteristics. These alloys offer improved mechanical properties while retaining the desirable attributes of pure titanium wire. The ongoing research and development in this field ensure that pure titanium wire remains at the forefront of modern materials science.

In conclusion, pure titanium wire undeniably stands out as an extraordinary material due to its exceptional properties and diverse applications. Its remarkable strength, lightness, and corrosion resistance make it an invaluable resource in industries such as healthcare, aerospace, marine, and automotive. Through advanced manufacturing processes and ongoing research, scientists and engineers continue to uncover new possibilities for this wonder material. Whether used in dental implants, aircraft components, or automotive exhaust systems, pure titanium wire exemplifies the true meaning of strength and purity.

Popular Products

Related Machining & Investment Casting News

Call Us

+86-917-3309953

Address

NO.59 JUFU ROAD, WEIBIN DISTRICT, BAOJI CITY, SHAANXI PROVINCE English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  Ελλάδα

Ελλάδα